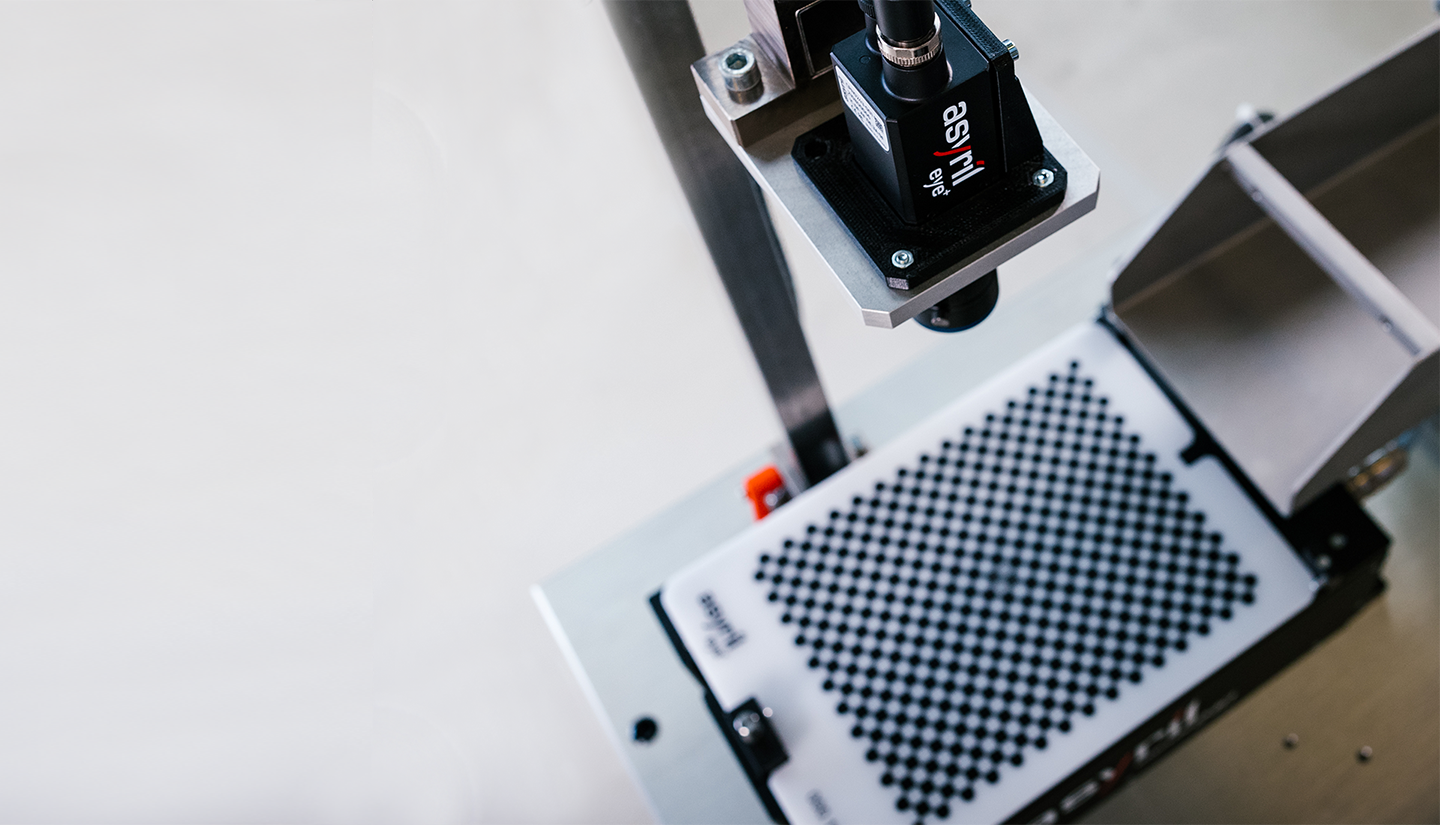

EYE+ smart control system

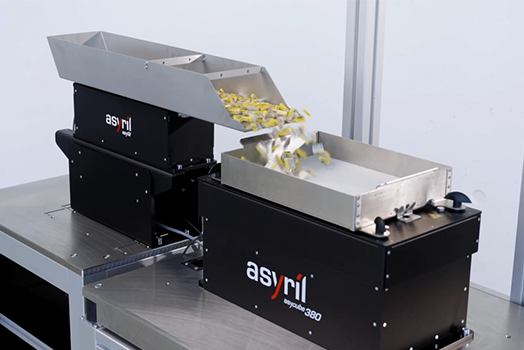

Your partner for efficient production.

EYE+ optimizes the performance of your Asycube flexible feeder with an integrated vision based on Artificial Intelligence and a powerful controller. With EYE+ you have an innovative plug and play system that can be easily integrated into any automation machine.